for our brochure

Retrofit Plenum

Retrofit Plenum

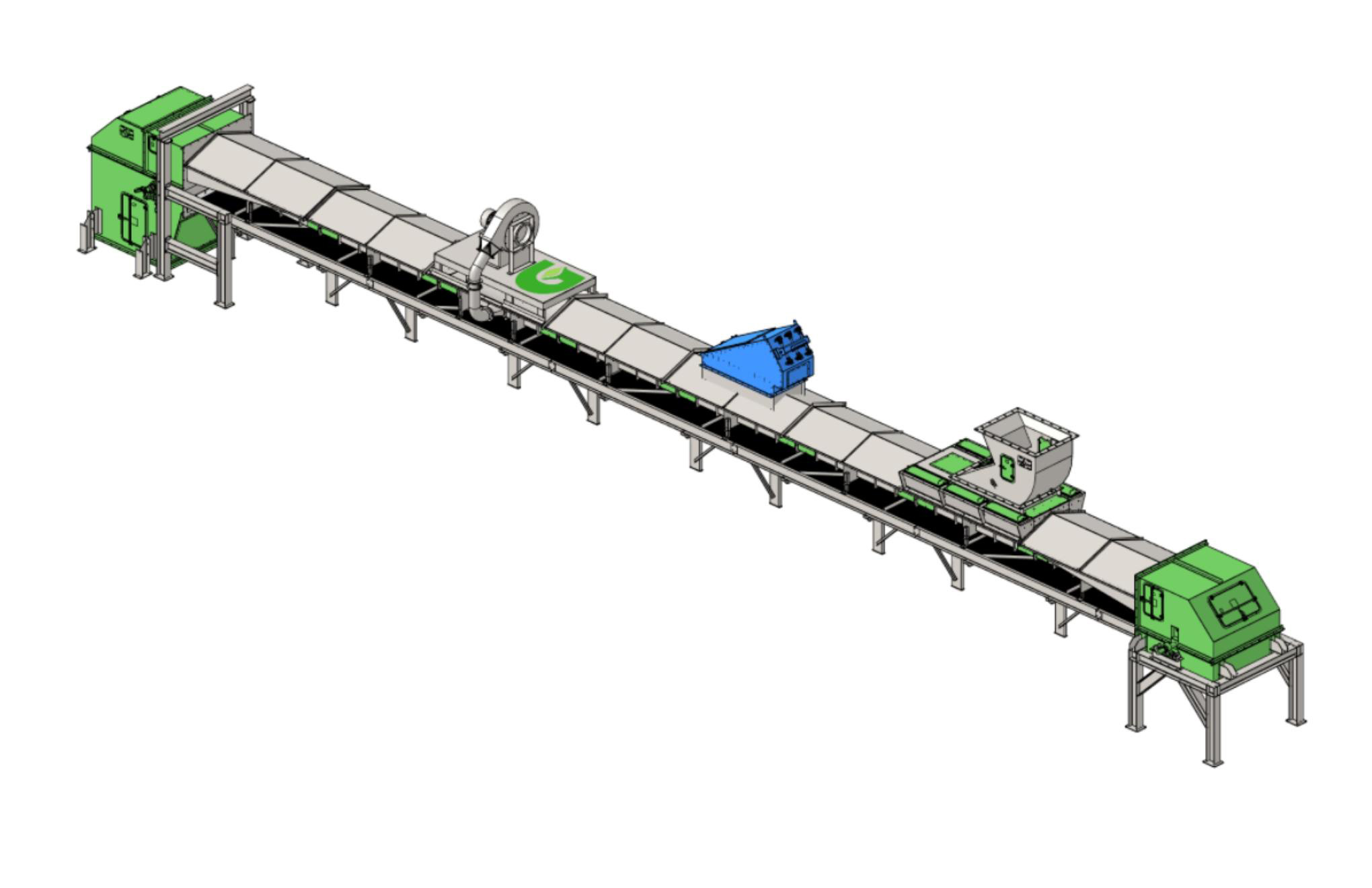

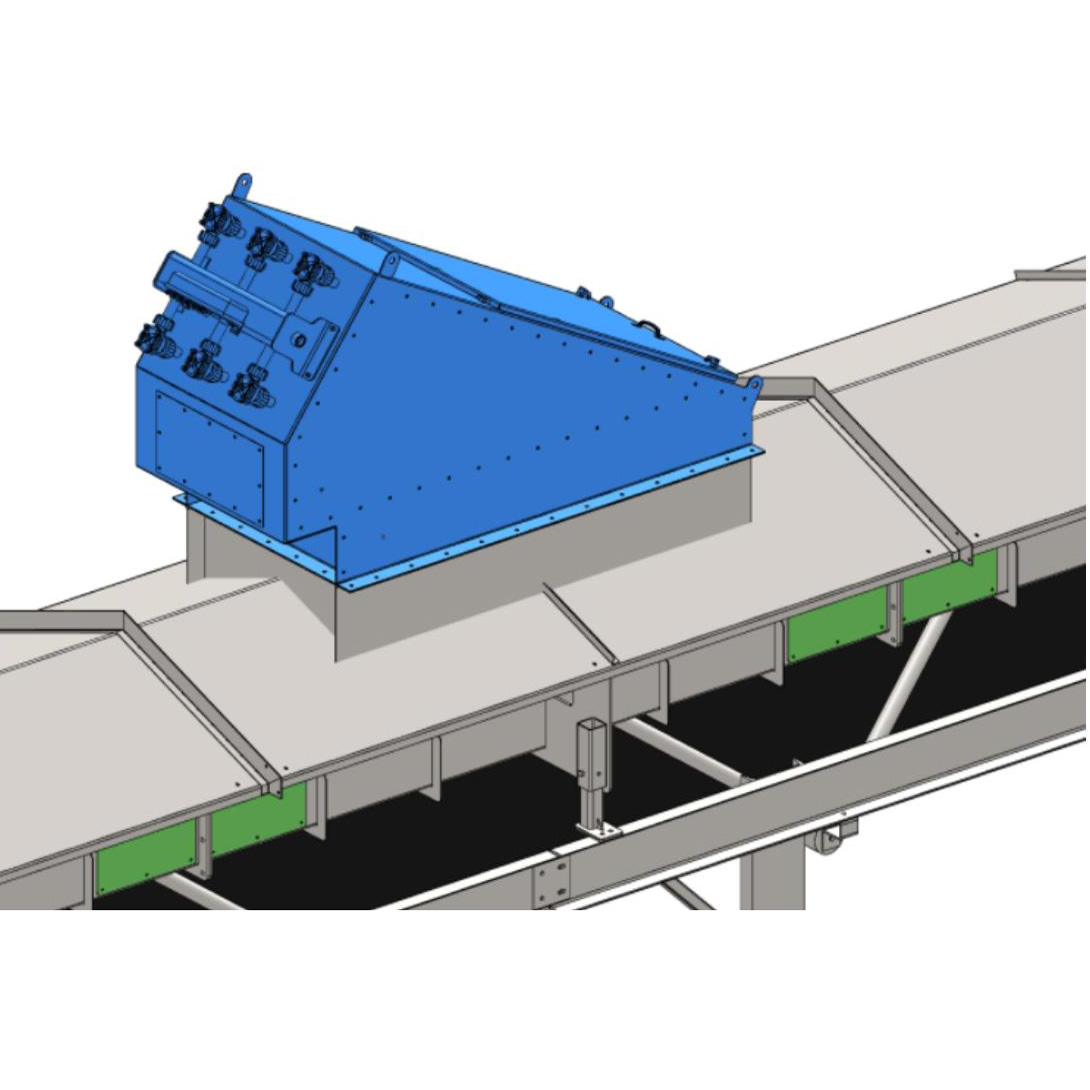

Grisley Retrofit – Grisley's air-supported retrofit plenum allows our customers to retrofit an existing traditional roller-based conveyor with a dust-tight and weather proof air supported system on the carrying side. The retrofit plenum is frequently used to help eliminate dust emitting systems while also eliminating the need for process air and baghouse systems. See our brochure for more in-depth capabilites of our Retrofit Plenum.

Upgrade your existing conveyor

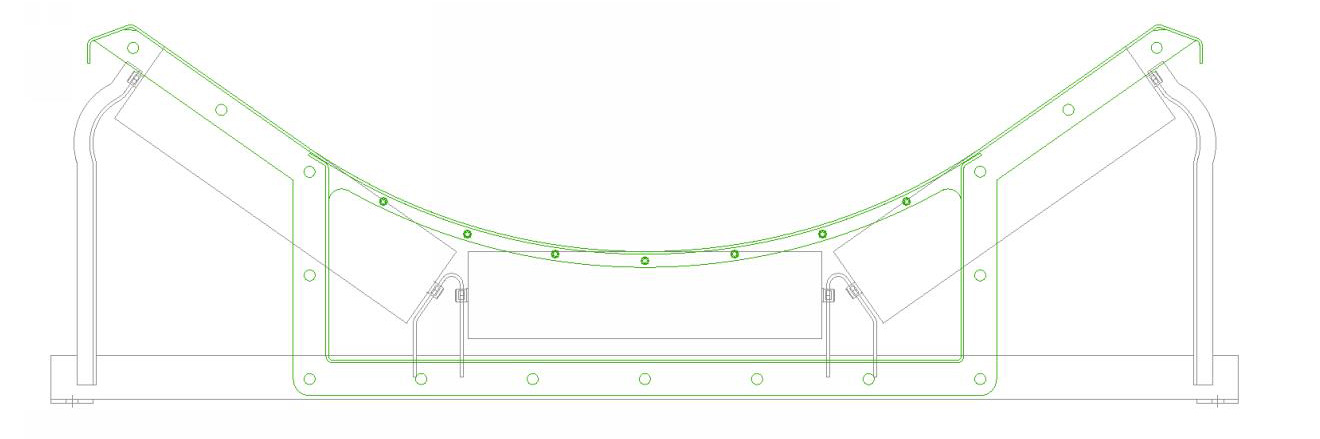

Grisley ASC is revolutionizing the way conveying systems control dust. With the combination of Grisley ASC's dust-tight conveyor design and Donaldsons CPV filtering technology we are cutting the costs and inefficiencies associated with dust collection. Design according to CEMA (Conveyor Equipment Manufactures Association) standards. The Retrofit Plenum utilizes the existing drive mechanisms and belt.

Simplify the retrofitting process and reduce cost

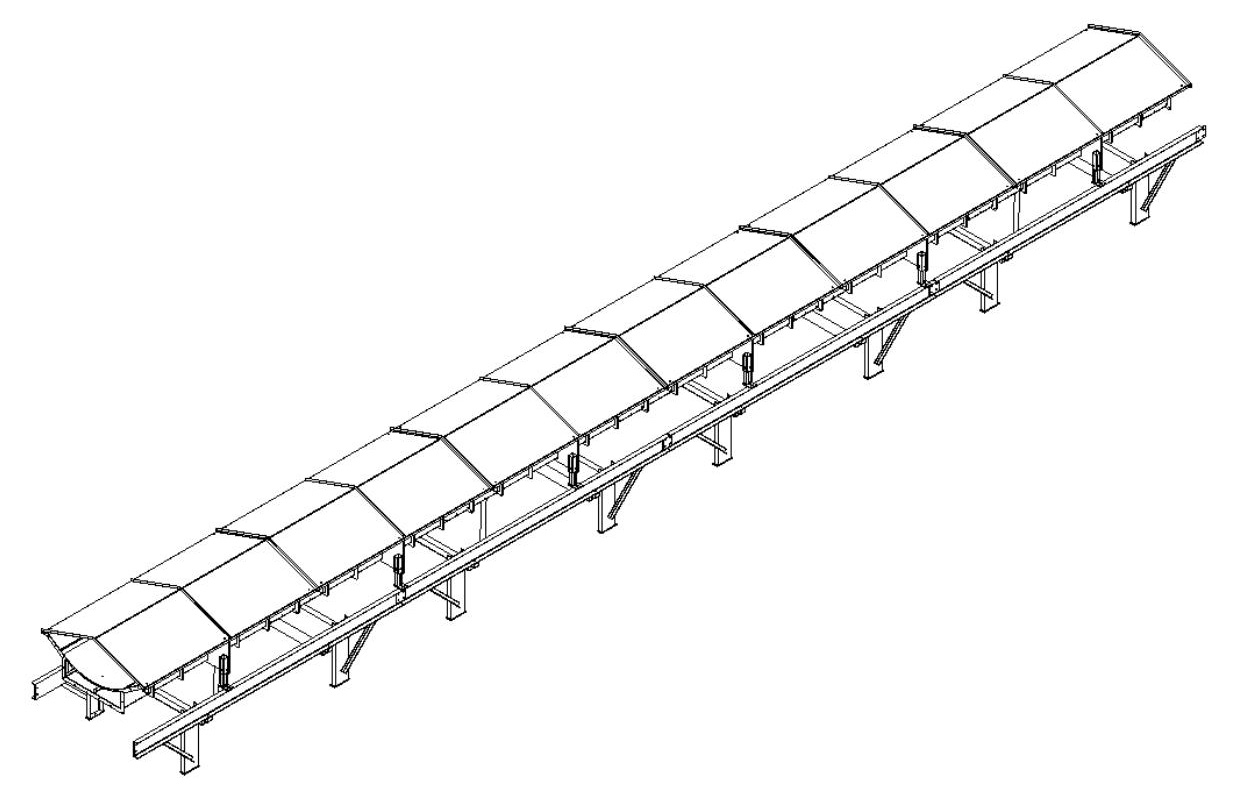

The Retrofit Plenum ships to site as a modular design that easily takes the place of the conventional conveyor troughing idlers. This requires very little to no upgrades of the existing conveyor support structure. This has an added advantage of eliminating the need for further retrofitting. by eliminating the source of friction and wear on moving parts. the retrofit plenum will substantially reduce the conveyor’s operating and maintenance costs.

Watch

Video

All of the benefits of air-supported conveying

The Retrofit Plenum is available at a competitive per-section cost compared to conventional rollers. The retrofit design provides all of the inherent benefits of air-supported conveying on the carrying side with substantial reduction in installation costs and downtime.